Two tiny terrors.

One built to bush bash, one built to push bass.

The question has to be asked: why? Why waste money on a Mighty Boy? Why individualise one of Australia’s least powerful and smallest utes? Why customise something barely bigger than a bread box and about as comfortable? Why face embarrassment and ridicule when meeting with friends and telling them what car you drive? Why do you always get red lights when you’re in a hurry? Why do so many people who like to drive at 20 km/h under the speed limit, also like to sit in the far right lane of freeways?

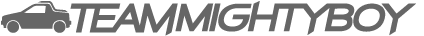

Why? Why, is exactly what we asked the creators of these two micro-sized mini trucks. Why not? Good enough we say! If you’ve got the balls, we don’t care what’s modified - as long as it looks great.Anthony Muddle, the builder of the up-in-the-sky 4WD Suzuki Mighty Boy, picked his project up as a write-off. Anthony has a thing for off-beat, challenging projects. Several years ago he was responsible for a particularly attractive Holden V8-powered Triumph TR7-based car which had more non-Triumph parts than Triumph. The same train of thought prevailed with his Mighty Boy. Anthony figured with a virtually free bodyshell and an old Suzuki 4WD, he could combine his interest of four-wheel driving and putting into practice wild ideas.

Boys to Men

Fast Fours and Rotaries

January 1995

Words

Glen Torrens

Photos

Mark Bean

The Mighty Boy was missing all of its front sheet metal and interior when Anthony got hold of it, but that didn’t faze him because most of it was to be chopped out anyway. The LJ80 donor car was picked up for a song, as these days they’re getting on in years and most fo the time the bodies are stuffed, making them ideal for projects such as this.

Mating the Mighty Boy shell to the 4WD chassis involved stretching the chassis 230mm in the wheelbase, as well as fabricating various brackets. Lots of time went into perfectly created inner front guards: what was left of the Suzuki sheetmetal was cut away and new inner skinning made form fresh sheet steel. The workmanship is first class and would do a race-preparation workshop proud.

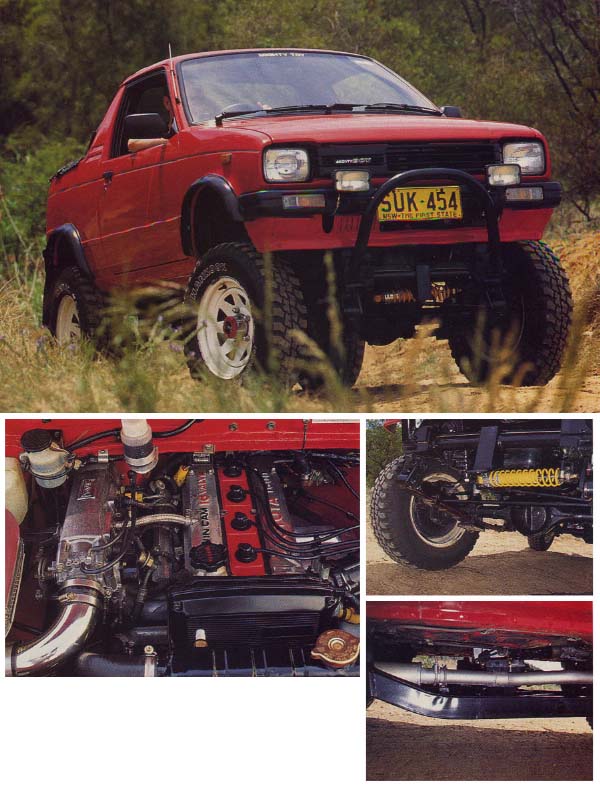

Bracing comes in the form of 25mm square section tubing forming a second set of ‘sort-of’ chassis rails. New front outer sheet metal from the windscreen forward painted in the original red completed the easy bits of the build.Complete with standard drivetrain, Anthony drove around for a while until the idea of more grunt occurred. The Toyota 1.6 litre twin cam 4A-GE motor seemed to be about the right size, price and power - so out came the tired Suzuki 4WD motor and in went the 4A-GE. Anthony made more sheet metal mods to the firewall and floor to make the new motor and T18 five-speed gearbox fit.

Squeezing a longitudinal four with a wide DOHC head into the space where a transverse, 500cc three used to be means that #4 cylinder and the bell housing sit almost directly behind the dash panel. The standard Suzuki transfer case was moved rearward on the chassis, its location being determined by fact that Anthony cunningly wanted to use the original front driveshaft at the rear, that way he would only have to fork out cash for a custom front one. Another custom driveshaft was made up to link the gearbox to the transfer case. About 20cm long, it is virtually two uni-joints welded back to back.

Various parts of the anatomy had to be cut, shut, squeezed and fiddled to allow the two shifts to reach up through the floor. The heater behind the dash had to be relocated because now there was a motor in the way and a home found for the 4A-GE’s brain box. The wiring loom and pedals had to be modified to clear the new lumps and bumps on the floor. The steering box had to be moved about 60mm from its original location to clear the new motor. Get the picture? It’s highly modified!

Various parts of the anatomy had to be cut, shut, squeezed and fiddled to allow the two shifts to reach up through the floor. The heater behind the dash had to be relocated because now there was a motor in the way and a home found for the 4A-GE’s brain box. The wiring loom and pedals had to be modified to clear the new lumps and bumps on the floor. The steering box had to be moved about 60mm from its original location to clear the new motor. Get the picture? It’s highly modified!

The axles on this beast are standard, although the front now carries a set of Sierra discs - an engineering requirement. A set of Bulldog front springs at standard height were made for the vehicle and the shots are Monroe gas units. Sunraysia wheels with decent sized tyres certainly make the original tyres look… um, small. The Mighty Bad Boy is in fact, just about the same height as the original Suzuki 4WD on which it was based, even though it looks a mile high. The RTA boys didn’t have a problem with registering the vehicle either, as Anthony did it the right way by consulting an engineer. That’s not to say the RTA boys didn’t break into fits of laughter when they first laid eyes on the thing, though. Of interest is the two compliance plates on the firewall, one for the body and one for the chassis.

Anthony doesn’t own his toy any more. The new owner is Bob Atkin. Bob is a Mini enthusiast from way back and Bob had this crazy idea of dropping a Mini body shell onto a Suzuki 4WD chassis… until he saw this. “Mate, I had to have it. I saw it on the Putty Road one weekend. I’d actually head about it at work but didn’t think anything of it until I saw it. Then I though, I want it. One of the guys at work knew who owned it, knew it was for sale, and gave me the number.” How’s that for good luck?

Bob is absolutely rapt in his new toy and after seeing it for myself, I can see why. “I bought it because it was unique. It’s also quite good off-road. People just stop and stare at it when it drives by, they can’t believe it. I drove past one guy on the expressway one afternoon also in a red Mighty Boy. You should have seen the look on his face!” Bob is not going to change anything that Anthony did to build the vehicle, “except the diffs. The ratios are too low. The thing revs its head off at cruising speed.” But it sure gets there quick!

The combination of the 90-odd kilowatts of power, light weight and short gearing means that the 0-100 spring uses all five speeds on the T18 box. The little taco needle and the driver’s left foot and arm are a flurry of movement. And of course 4WD means hard launches. So far the standard transfer case, designed for about 30 kilowatts has soaked up the treatment dished out to it by the Toyota. The shortish wheelbase and leaf springs means the car pitches around a bit, so a performance car it ain’t. But that’s not the idea. This car is designed to be fun - with a capital ‘F’.

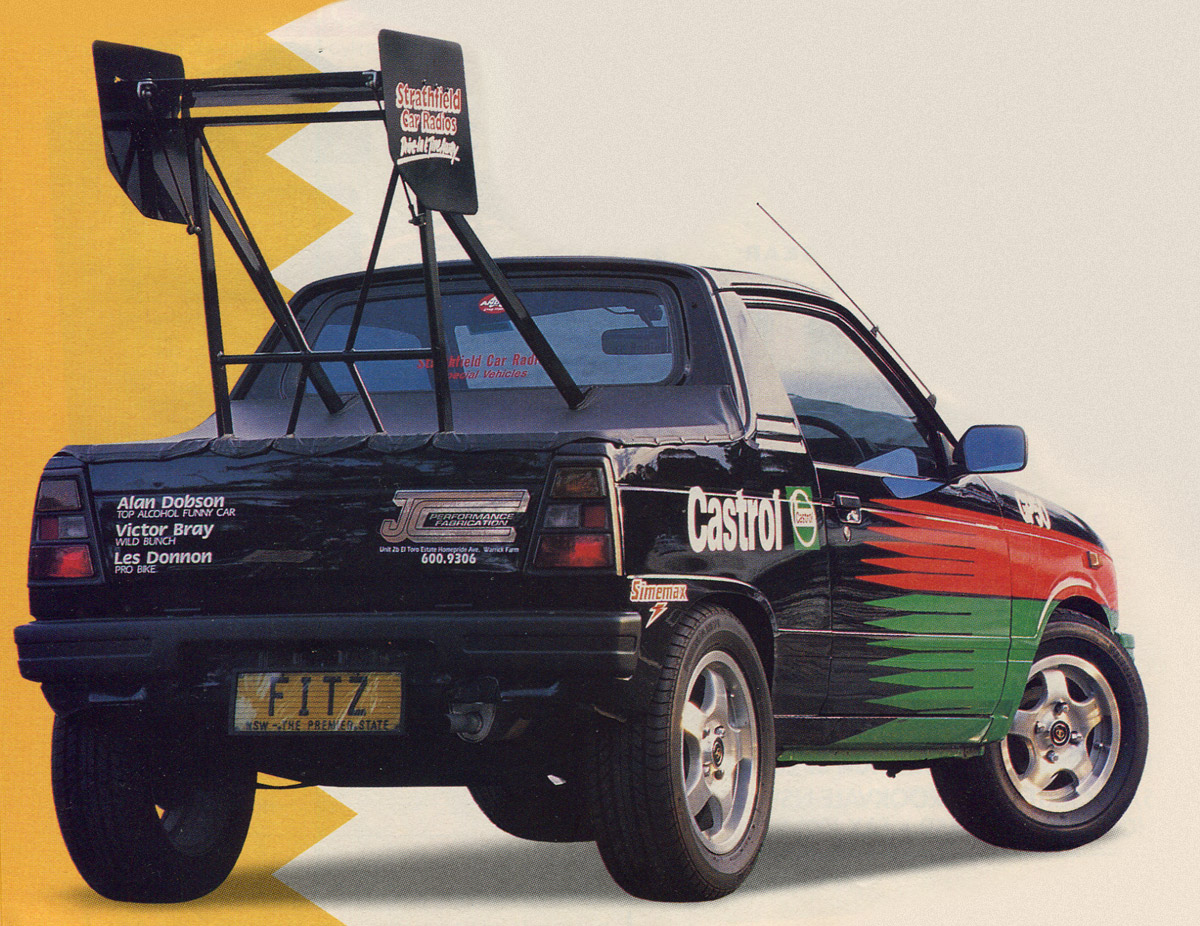

‘Fitz’s’ Mighty Boy is a completely different story. He’s a larger than life bloke with a constant crazed grin on his face and more tall stories than the claims section of an insurance company. His car was build as a rocking, rolling mobile billboard for Strathfield Car Radio at Artarmon, as well as Fitz’s involvement at the Castrol Drag Racing Team. The Mighty Boy is his daily driver.

Fitzy bought it originally to use as a promotional toy for Castrol Australia while he was running his drag Holden at Eastern Creek. Painted black by High Performance Smash Repairs at Revesby, and with that wicked looking Top Fuel wing on the back, it draws attention. Usually funny looks, followed by side-splitting laughs.

Forget what’s under the bonnet, (Fitz is not even sure what’s under there) - it’s what’s inside and under the back that counts - pure unadulterated decibels. The head unit to this system is a Sony CDX-5270 CD tuner. It fits in the standard DIN cutout in the dash and feeds to a pair of amps: a Punch 100 IX and 200 IX. Wired in parallel to the amps ins a Punch cap, a beer can sized capacitor that soaks up charge and keeps the voltage level constant when the amplifiers momentarily drawing big current to feed the woofers.

A Streetwires fuse box protects the amp/cap combo. All of these components are mounted on crafted panels in the small area behind the front seats. A fluoro tube above the amps keeps the Freds happy when they’re stickybeaking at night. Also in the rear of the cabin is a pair of EQT One-Third Octave Constant-Q Precision Equalisers and the MB Quartz crossovers. In the front footwells are two handcrafted speaker enclosures housing a pair of MB Quartz QM328CX three-ways. Fill-in in the centre is a 4-inch Rockford mid-range housed in the dash. There are a couple more rear-fill 4-inch Rockfords mounted in the B-pillars just below the seatbelts.

You won’t be throwing your tools in the bak of this bubba ute, because filling the tray below that wing is a big box housing a pair of 10-inch Punch Classic Audiophile RFA 1-4 woofers. Two six-inch ports vent into the cabin. Using a bandpass style of enclosure, the front of the twins breathe into the left port straight onto the passengers seat. While the rear feeds the right. The top surface of the enclosure, level with the top of the tray, is see-through, so pulling back the tarp reveals a lurid display of spattered pink and green workings. As the intention was to showcase the improving workmanship of SCR, grabbing attention was the primary objective. All of the installation work in this ute was done at SCR at Artarmon, and took three weeks of work, on and off.

Gee Fitz, what’s it go like? Well, believe it or not, Fitz has put it down the Eastern Creek quarter mile. The powerhouse three cylinder donk and two-speed auto-equipped Thunder Boy laid down a 32.28 second pass - suffice to say the power of this car lives in the tool tray, not in the engine bay.