Turbocharging an F8B

The question about adding power to a MightyBoy often leads to the answer of an engine swap - usually from the original 543cc F5A engine to the larger 796cc F8B. From there, the next logical step is adding a turbo to the mix.

There are many different ways to tackle a turbo upgrade, and if you have (or are) a skilled metal fabricator the options are limitless.

This guide is simply one method, centred around adapting parts from a Suzuki F6A engine for ease of installation and lower costs.

Please note:

Turbo conversions on N/A engines require certification by a qualified engineer to be legal for road use in Australia, as specified in current Australian DOTARs legislation - the National Code of Practice (NCOP) for Light Vehicle Modifications.

Turbo conversion process

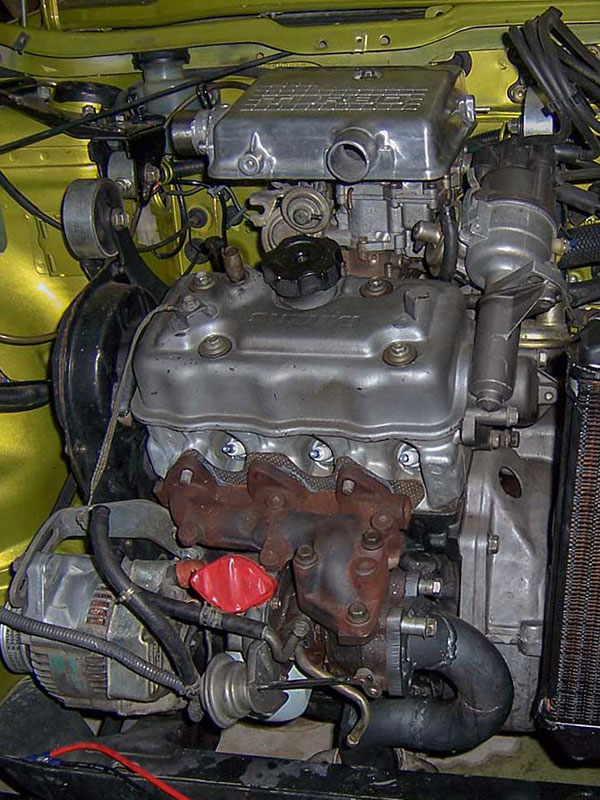

This conversion method uses parts from a Suzuki F6A single cam engine, including the complete inlet manifold, exhaust manifold and turbo, plus the distributor. (A full list of required parts is provided further down the page.)

The F6A parts from a Suzuki Alto or Jimny will bolt directly onto an F8B engine without modification, however some machining is required to port match the manifolds to the F8B head for improved performance.

Installation can be done with the motor in the engine bay, but it is much easier with it removed. There are minor clearance issues in some places, however these are simple to address. If a Jimny inlet manifold is used then the thermostat housing will be on the left side, which will need to be routed across to the radiator with some extra piping.

Installation can be done with the motor in the engine bay, but it is much easier with it removed. There are minor clearance issues in some places, however these are simple to address.

Factory F6A (single cam) exhaust manifold and turbo

Despite the compact the log-style factory manifold it is still a very tight fit, even before the front mount intercooler and piping are installed! The radiator (from a Leyland Mini) provides adequate clearance for a custom exhaust dump pipe.

Required parts and budget

Here's a rundown of the parts you need and roughly what they will cost you.

(January 2022, and assuming full retail is being paid)

Suzuki F6A parts

Alto is preferable because the thermostat housing is on the same side as the MB radiator, but Jimny will also work with some extra piping.

(single cam F6A only - twin cam parts will not fit an F8B engine)Inlet manifold - $100 to $200

Best to get this complete with all sensors, throttle body, injectors and fuel rail. The manifold will bolt directly to the F8B head, however it does require port matching for best results.

Exhaust manifold and turbo - $100 to $500

When buying second hand there's a risk that the turbo will be roached, so you might choose to have a custom exhaust manifold made and use a different turbo than the factory IHI-RHB31.

Distributor and rotor button/cap - $50 to $100

The F6A has an electronic ignition, and the distributor is a direct fit into the F8B housing.

ECU and wiring harness - $200 to $500

This is optional, because to be honest you're far better off using an aftermarket stand alone ECU solution than trying to adapt the factory system.

Ignition system

Aftermarket ECU - $1500+ (not including tuning)

An alternative to adapting the factory F6A ECU is to install a standalone aftermarket system. This provides far more scope for improving performance through tuning, and circumvents limitations of the factory ECU.

Ignitor and coil(s)- $300+

You will need the appropriate ignitor module and coil(s) for your ECU setup. The factory F6A uses batch fire, which requires a single ignitor and coil, however you might choose to run full sequential which will require 3 coils.

Fuse box, relays and wiring $100-200

The F6A electronic ignition system requires upgrades to the factory MightyBoy wiring, including replacement of the 9V ballast resistor system to run constant 12V, and a variety of relays and fuses for fuel pumps, etc.

Fuel system

Fuel pressure regulator (and gauge) - $200+

Get a genuine, high quality EFI fuel pressure regulator. Cheap knockoffs have been known to rupture and start engine bay fires.

Fuel pumps and surge tank - $500+

A single high pressure EFI fuel pump is required as a minimum, but you can choose to add a small surge tank and low pressure lift pump for added protection against fuel surge.

Fuel lines and fittings - $100+

The standard fuel lines aren't large enough to cope with EFI fuel flow. The cheapest upgrade is to use alloy/steel hard lines, EFI fuel hose and brass fittings with hose clamps. For a few hundred dollars more you can upgrade to AN fittings and lines, which are safer and more durable.

Turbo plumbing

(oil, water, air, exhaust)

Oil/water feed and drain lines - $200+

Stainless braided lines and fittings are recommended to cope with the heat and ensure reliability. The sump requires removing and a fitting welded on to connect the turbo oil drain.

Dump pipe and exhaust - $500+

The standard F6A dump pipe (from an Alto) can be used however it is not ideal as it doesn't line up with the F8B sump recess. A custom-made dump pipe allows better placement/flow. Either way, a full 1.75" exhaust system is a good upgrade, with a flex joint to prevent the exhaust manifold cracking.

Intercooler and piping - $200+

This cost will vary greatly depending on the size and placement of the intercooler. A top mount is cheapest (not factoring in bonnet modifications for ventilation) with a front-mount requiring more piping and silicone hose joiners.

Supporting modifications

(There are a few other parts that aren't necessarily required, but will improve performance/reliability)

Radiator and fan - $300+

Depending on how you route the dump pipe, the factory radiator might not fit. A simple upgrade is a new replacement unit from a Leyland Mini, which can be easily adapted to fit. It has more cores for improved cooling capacity and a thinner width to provide clearance from the turbo and exhaust. Pair it with a good quality fan for best results.

Alternator - $100+

The factory MightyBoy alternator puts out a paltry 25 amps, which is hardly enough to run an EFI ignition system and fuel pumps. There are several upgrade options available - the easiest being a Suzuki Swift GTI unit (with a pulley swap) providing 60A in a small package.

Clutch - $100+

A standard clutch is suitable for up to around 10PSI of boost pressure, where it will start to suffer from slipping. Exedy offer a heavy duty unit that will prevent this problem.

Gauges

With a modified engine it is a good idea to have a few gauges to keep an eye on things like oil/fuel pressure. This might be possible through your chosen ECU. If not, use standalone gauges.

Brakes - $500+

Standard MightyBoy brakes won't provide enough stopping power for spirited driving, period. The cheapest and most straightforward upgrade is a set of dimpled/slotted rotors and decent pads. If that's not enough, look at hub swaps from Swifts, or other small FWD cars with ventilated front rotors.

Alternative methods

Carburettor (draw or blow through)

This can be done a couple of different ways. One is to use a draw-through setup (carby before the turbo), and the other is a blow-through (carby after the turbo). There's a good write up of the basics on draw/blow through turbo setups over on the Datsun 1200 forum.

Either method requires the factory distributor to be regraphed, altering the ignition curve to compensate for added boost pressure to prevent detonation. Finding specialists with that skillset is becoming more difficult as carburettors and mechanical distributors become less common. Upgrades to the fuel system are also required, including a fuel pump (that supplies slightly more fuel pressure than whatever boost pressure you are running) and larger fuel lines.

Without major modifications, a standard F8B engine will cope with about 7PSI of boost pressure using a carburettor setup, assuming the fueling and ignition timing are right.

Draw through

A draw-through turbo setup can be done with any appropriate size carby (1.75" SU is popular) however the downside is that an intercooler can't be used. This means intake temperatures can get quite high, and engine detonation needs to be carefully managed through ignition timing or decompressing the motor.

Blow through

A blow-through setup requires the carby from a Daihatsu Charade CB23, or a pressure box to be built around a suitable non-turbo carby. This prevents the seals in the carby from leaking when boost pressure is added. (The Charade carby requires a small (~8mm) spacer plate to provide clearance for throttle linkages.)

While a draw-through setup is arguably easier, the benefit of a blow-through design is that the carby sits in the factory position on the inlet manifold, and means an intercooler can be used, which reduces intake temperatures and lowers the risk of detonation. Finding suitable parts from a Charade can be a challenge.